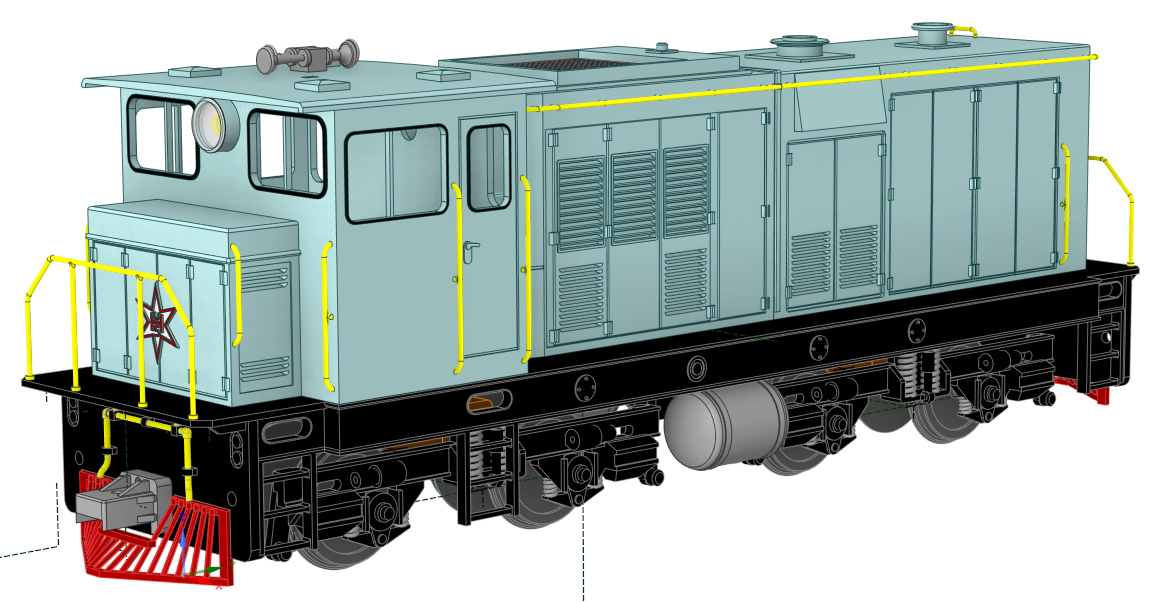

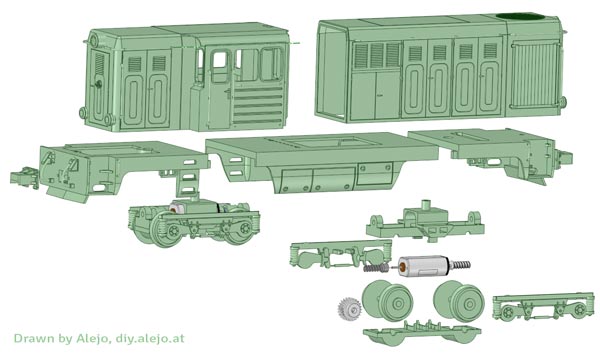

0 scale Henschel DHG 1000 like narrow gauge diesel

based on drawings of EAR - Class 61

source: rogerfarnworth.com

3D design, Chassis will be designed to fit 16.5 mm, 19.05 mm and 22.5 mm track gauges. The prototype is built for meter gauge.

Other slicing software - different results - but, the whole thing becomes printable. Some adjustments here and there to counteract the deformation of the prints are still necessary.

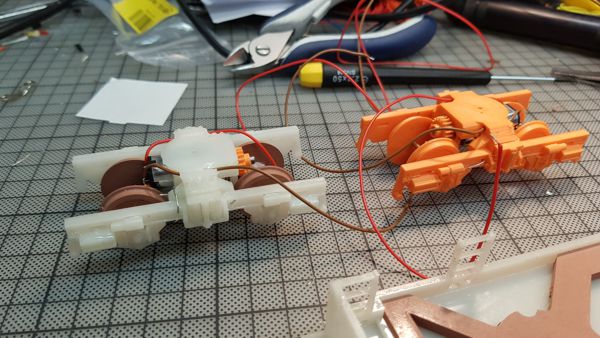

Chassis in comparison: left, printed on the Elegoo Mars - right, printed on my Witbox 2.

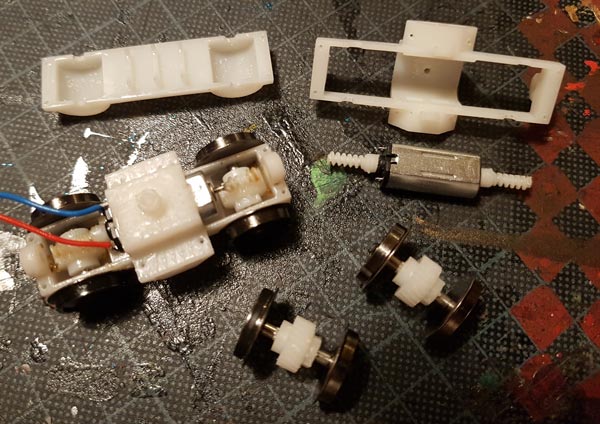

Printed using the original Elegoo black resin - directly from the printer the results were good. As I did not have access to my curing station, the parts did not cure sufficiently and bent.

For driving tests and to verify the fit of the components, the parts are useful - in the meantime, new parts are printed in good quality and are waiting for assembly and painting.

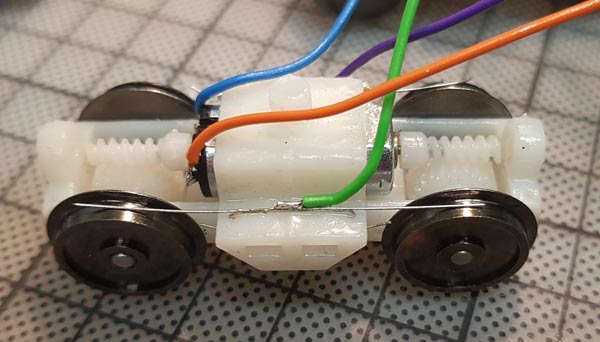

Unlike the L45H, the wheels are printed on this design. The locomotive is powered by batteries. Via a simple Arduino 2.4GHz connection the model can be remote controlled. More then in the section "Electronics" (coming soon) .

And wow, this beast is really big! But also ingenious in tight curves (r=360mm). Thanks to the gear motors it also runs very slowly.

still the bent and broken cab,but hey, what heavy used machine has no damage?

New engineers cab and tanks added

0n30 Faur L45H - the first to be 3d printed

Times change... and so I turned to new technologies - 3D printing.

SLA Printers seem to be the right way to go in small scale modelling. Having different types on hand, drawings were made for test-prints. As the results have been pretty awesome, drawing continues....

3D Model of a L45H like loco in 1/4inch scale to run on 16.5mm track.

Drawn in DesignSpark Mechanical

Painted test-print (Form2).

The Formlabs Printers are awesome in resolution. Also it takes a lot of time for printing and post processing like curing and cutting of the supports. SLA UV LCD printers are much faster. Since I am not a "rivet counter" I can live with the lower resolution because I have other advantages such as almost no supports.

Since the print area on my Elegoo Mars is much smaller than on the Form2, I had to split the parts.

First unpainted sample, test run done - have to check the pickups....

First layers of colour...

3d printed prototype of powered bogie, worm gear and gear wheel modul 0.4- all printed!!

improved gearing and pickups - violin string wire as current collector

-waiting for sides to be printed to complete the bogie

first test run

closeup

exploded view: only wheel-sets, motor, couplers and screws are 3rd party...

lights still missing :-)

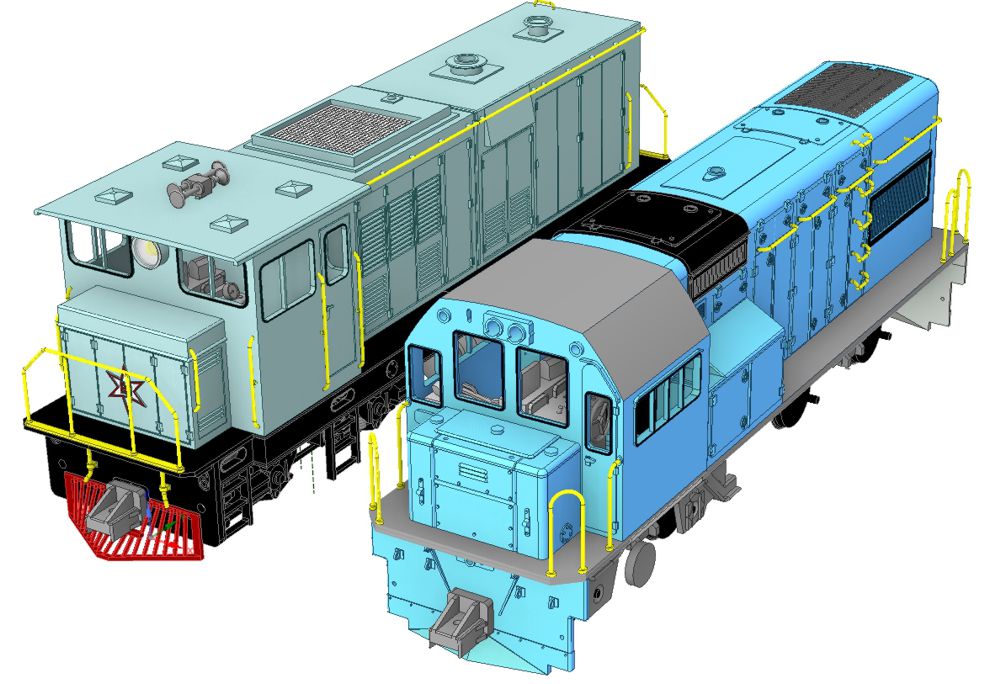

3d printed NG diesel based on a GE UM6B design

3D design still in process- truck-design taken from the DHG 1000 model will be modified to fit the GE. As I can not find quality drawings of this engine, drawing these trucks in detail is not possible - the result will be no more than a guess through photos....

After the printing and assembly experiences made with the DHG 1000, a number of things can already be taken into account for the further development of the GE machine. This locomotive will again be remote controlled and battery operated.

wow, I can print a grid about 0.3mm thick and shaped....

3 different technologies.... left elegoo mars, right form2

Housing parts and details are printed with the Elegoo Mars (2Pro), the chassis parts I prefer to print on the Witbox, the parts are a bit more durable.

and here some test parts printed on a BQ Witbox2, 0.2mm nozzle

The comparison demonstrates: the GE machine is also quite large for narrow gauge!

Photo etched brass construction

Diesel Switcher

freelanced model, made of photo etched brass (my first try in this technique), chassis taken from an old Kleinbahn steam loco, fitted with a new motor.

Faur Diesel, since decades in cue.... will it ever be finished?